|

Brand Name |

GRMOT |

| Warranty |

3 years |

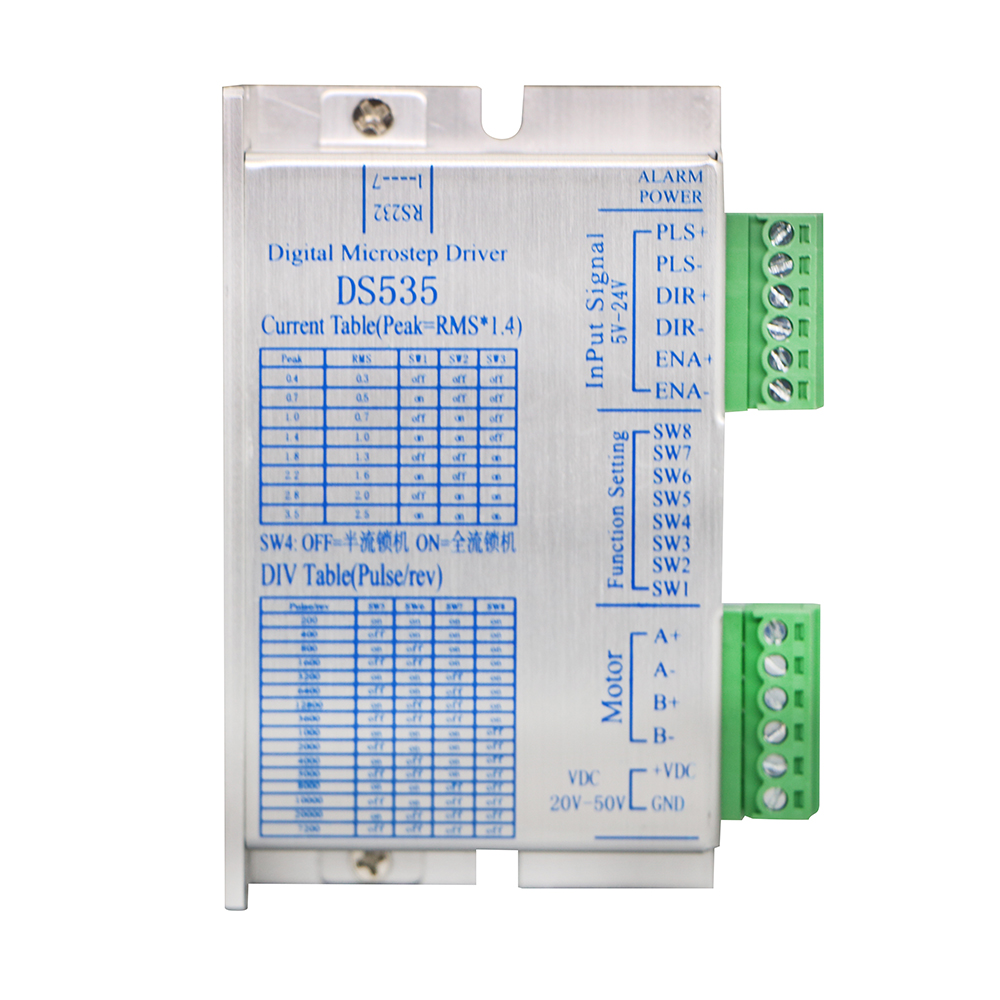

| Model Number | DS535 |

| Product Name | Motor Driver |

| Output Current(peak value) |

0.3-3.5A |

| Supply Voltage | 20-50VDC |

|

Recommend Matching Motor |

28/35/42 Motor Size |

| Working Environment Temperature | -20℃~+50℃ |

1. Overview

DS535 is a two-phase digital stepper driver with serial port debugging function newly launched by Gree IoT Technology Co., Ltd. It adopts the latest 32-bit DSP control technology and integrates MODBUS-RTU standard protocol specifications. Users can set multiple parameters such as subdivision and working mode within 200-40000 through the upper computer debugging software, greatly enriching the practical functions of the product and meeting the application needs of most occasions.

The DS535 driver adopts a servo like control principle, integrating vector control technology, built-in micro segmentation technology, and adaptive filtering technology, greatly optimizing the performance of the stepper motor. It runs smoothly at low, medium, and high speeds with low noise. The precise and smooth pure sine current vector control technology effectively reduces motor heating.

The driving voltage range of DS535 driver is DC20~50V, suitable for two-phase hybrid stepper motors with peak current below 3.5A and outer diameter of 28~42mm.

2. Characteristics

● Equipped with serial port debugging function ● New 32-bit DSP technology

● Small size, easy to install ● Can drive 4, 6, and 8-wire two-phase stepper motors

● Optical isolation differential signal input ● Built in micro segmentation

● Subdivision setting range of 200-40000 ● Pulse response frequency can reach up to 200KHz (higher can be adjusted)

● Current can be set arbitrarily ● Precise current control greatly reduces motor heating

● It has protection functions such as overvoltage, undervoltage, overcurrent, etc. ● The current automatically halves when stationary

3. Application Fields

Suitable for various small and medium-sized automation equipment and instruments, such as engraving machines, marking machines, cutting machines, plotters, CNC machine tools, automatic assembly equipment, etc. The application effect is particularly good in devices where users expect low noise and high speed.

| Parameter | Parameter | Parameter | Parameter | Parameter |

|---|---|---|---|---|

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |

| Parameter | Parameter | Parameter | Parameter | Parameter |