The standard closed-loop stepper motor is a type of stepper motor that integrates a closed-loop feedback system. It provides real-time feedback on the motor's position and speed information through an encoder, achieving precise position control and performance optimization.

Closed loop stepper motor product series models and parameters:

NEMA 17 Closed Loop Stepper Motors

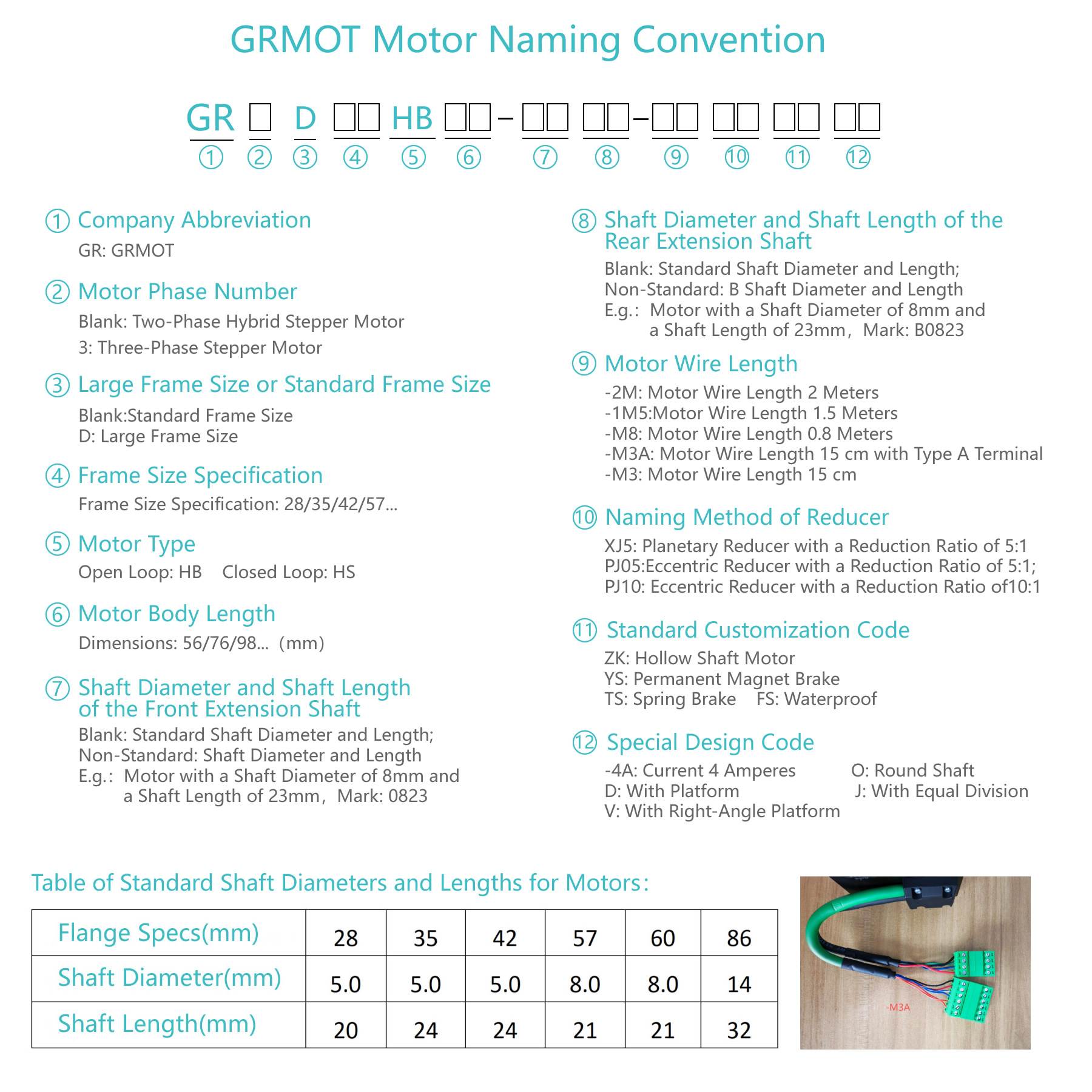

| Model | Frame Size (NEMA) | Length (mm) | Holding Torque (N.m) | Shaft Diameter (mm) | Phase Current (A) | Rotor Inertia (g.cm²) | Encoder Resolution (PPR) | Match driver |

| GR42HS48-3M | 17 | 48 | 0.6 | 5 | 2 | 60 | 1000 | HS1-42 |

| GR42HS60-3M | 17 | 60 | 0.8 | 5 | 2 | 86 | 1000 | HS1-42 |

NEMA 23 Closed Loop Stepper Motors

| Model | Frame Size (NEMA) | Length (mm) | Holding Torque (N.m) | Shaft Diameter (mm) | Phase Current (A) | Rotor Inertia (g.cm²) | Encoder Resolution (PPR) | Match driver |

| GR57HS56-3M | 23 | 56 | 1.3 | 8 | 4 | 280 | 1000 | HS1-57 |

| GR57HS80-3M | 23 | 80 | 2.4 | 8 | 5 | 350 | 1000 | HS1-57 |

| GR57HS86-3M | 23 | 86 | 3 | 8 | 5 | 380 | 1000 | HS1-57 |

NEMA 24 Closed Loop Stepper Motors

| Model | Frame Size (NEMA) | Length (mm) | Holding Torque (N.m) | Shaft Diameter (mm) | Phase Current (A) | Rotor Inertia (g.cm²) | Encoder Resolution (PPR) | Match driver |

| GR60HS86-3M | 24 | 86 | 3 | 8 | 5 | 420 | 1000 | HS1-57 |

| GR60HS86-30-3M | 24 | 86 | 3 | 8 | 5 | 420 | 1000 | HS1-57 |

NEMA 34 Closed Loop Stepper Motors

| Model | Frame Size (NEMA) | Length (mm) | Holding Torque (N.m) | Shaft Diameter (mm) | Phase Current (A) | Rotor Inertia (g.cm²) | Encoder Resolution (PPR) | Match driver |

| GR86HS80-3M | 34 | 80 | 4.5 | 14 | 6 | 1800 | 1000 | HS1-57 |

| GR86HS118-3M | 34 | 118 | 8.5 | 14 | 6 | 2700 | 1000 | HS86HV |

| GR86HS156-3M | 34 | 156 | 12 | 14 | 6 | 4000 | 1000 | HS86HV |

Gree's closed-loop stepper driver supports closed-loop stepper motors with flange sizes of 28-86

There are currently no relevant documents available